Creating Efficiency: How Brush Machines Improve Cleaning Processes

Creating Efficiency: How Brush Machines Improve Cleaning Processes

Blog Article

In today's fast-paced world, maintaining cleanliness and hygiene is more critical than ever, especially in industrial and commercial settings. The efficiency of cleaning processes can make a significant difference in productivity and overall operations. One of the key innovations improving these processes is the brush machine, a vital tool that streamlines the production of cleaning equipment. With advancements in technology, brush machines have become essential for manufacturers, enabling them to create high-quality brushes quickly and efficiently.

At the forefront of this innovation is Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. With 37 years of experience and deep technical expertise, this professional company specializes in producing 2-5 axis machines that cater to various brush-making needs. Their commitment to quality and efficiency has positioned them as a leader in the industry, helping businesses enhance their cleaning processes and achieve greater productivity.

Overview of Brush Machines

Brush machines are essential tools in various industries, designed to automate and streamline the cleaning process. These machines utilize advanced technological features to ensure efficient production and consistent quality in brush manufacturing. By employing different types of machinery, companies can address various cleaning needs, such as surface preparation, polishing, and final touch-ups, enhancing the overall productivity of their cleaning operations.

One significant player in the brush machine industry is Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. With 37 years of production experience, this company has established itself as a leader in producing high-quality 2-5 axis machines. Their technical expertise allows them to craft machines that not only meet the demands of modern manufacturing but also improve the efficiency of cleaning processes across different sectors.

The adoption of brush machines enables manufacturers to scale their operations while ensuring precise cleaning outcomes. As businesses continue to strive for better productivity, the importance of reliable equipment like those provided by Jiangmen Meixin cannot be overstated. These machines facilitate faster production rates, lower labor costs, and enhanced cleaning quality, significantly impacting the cleaning industry’s operational efficiency.

The Importance of Automation in Cleaning

In today's fast-paced world, automation has become an essential component of many industries, including cleaning processes. The integration of automated systems, particularly brush machines, enhances efficiency and ensures consistent cleaning results. This shift allows businesses to streamline their operations, reduce labor costs, and improve overall productivity. As companies seek to meet rising consumer demands, the role of automation in maintaining cleanliness and hygiene standards becomes increasingly significant.

Brush machines, such as those produced by Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd., play a vital role in automating cleaning tasks. These specialized machines are designed to handle various cleaning applications, allowing for thorough and effective cleaning without the need for manual intervention. With 37 years of experience in the industry, Jiangmen Meixin has perfected the technology behind brush machines, maximizing their capabilities and ensuring they meet the highest standards of performance and reliability.

Moreover, the adoption of automated cleaning solutions contributes to sustainability efforts by reducing water and chemical usage. Automation leads to less waste and more efficient resource management, addressing environmental concerns while maintaining cleanliness. As the trend towards green practices continues, businesses that invest in brush machines will not only improve their cleaning processes but also align themselves with sustainable goals that resonate with modern consumers.

Jiangmen Meixin's Expertise

Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. stands as a leader in the brush machine industry with nearly four decades of dedicated experience. This extensive background has enabled the company to refine its production processes and develop advanced techniques that set them apart from competitors. The expertise gained over 37 years is reflected in their commitment to quality and innovation, ensuring that their machines meet the evolving needs of customers worldwide.

The focus on 2 to 5 axis machines showcases Jiangmen Meixin's ability to cater to a diverse range of applications. These machines have been engineered to provide precision and efficiency in the manufacturing of brushes, significantly enhancing productivity in cleaning processes. The technical accumulation achieved by the company not only allows for superior machine operation but also ensures reliability, ultimately leading to customer satisfaction in various industries.

Moreover, Jiangmen Meixin's reputation is built on their continuous improvement and adaptation to market trends. By staying ahead of technological advancements, they are able to offer products that not only incorporate the latest features but also address the specific demands of the modern cleaning industry. This forward-thinking approach positions Jiangmen Meixin as a trusted partner for businesses seeking to optimize their cleaning processes through the use of high-quality brush machines.

Advantages of 2-5 Axis Machines

The use of 2-5 axis machines in the brush manufacturing process offers significant advantages, particularly in precision and flexibility. These machines are capable of producing complex brush shapes with intricate details that are essential for effective cleaning. The multi-axis capabilities allow for precise movements and adjustments, ensuring that every brush meets strict quality standards. This level of accuracy not only improves product performance but also enhances customer satisfaction.

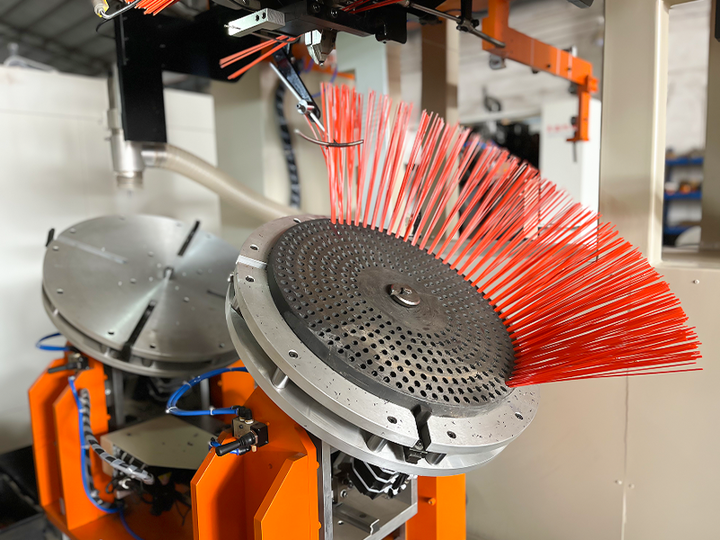

Brush Machinery

Another key advantage of 2-5 axis machines is their efficiency in production. With automated processes and the ability to handle multiple operations simultaneously, these machines reduce the time and labor required to manufacture brushes. This increased efficiency translates to lower production costs and faster turnaround times, making it easier for manufacturers to respond to market demands. As a result, companies like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. can maintain a competitive edge in the industry.

Additionally, the versatility of 2-5 axis machines allows manufacturers to innovate and diversify their product offerings. These machines can adapt to different brush sizes, shapes, and materials, enabling the production of a wide range of cleaning tools. This adaptability is crucial in a market that constantly evolves with new cleaning technologies and preferences. By leveraging the capabilities of 2-5 axis machines, manufacturers are empowered to expand their product lines and meet diverse consumer needs efficiently.

Future Trends in Cleaning Technology

As the demand for efficient cleaning solutions continues to rise, the cleaning technology landscape is evolving. Innovations in brush machines are at the forefront, catering to various industries. Companies like Jiangmen Meixin Comb Brush Making Machine Manufacturing Co., Ltd. are leading the charge, employing cutting-edge technology in their 2-5 axis machines to enhance production capabilities. This trend indicates a shift towards more automated and intelligent systems that offer precise cleaning solutions while reducing labor costs.

Sustainability is becoming increasingly important in cleaning processes. Manufacturers are exploring the use of eco-friendly materials and energy-efficient machinery. By integrating these considerations into their production lines, brush machine factories can develop products that not only meet cleaning demands but also adhere to environmental standards. This focus on sustainability resonates with consumers and industries looking to lessen their ecological footprints.

Another significant trend is the integration of smart technology in cleaning systems. Advanced software and IoT capabilities are enabling brush machines to communicate and self-optimize in real-time. This level of automation ensures that cleaning tasks are performed with maximum efficiency and minimal human intervention. As manufacturers like Jiangmen Meixin continue to innovate, we can expect brush machines to play an even more vital role in transforming cleaning processes for the future.

Report this page